Innovation business

Print

There is a wide range of materials in Ethylene Vinyl Acetate, EVA has such a wide use because it is unassailable by fungi and bacteria and in some cases can have an hypoallergenic and antitoxic treatment, as well as being a flexible and elastic product.

There is a wide range of materials in Ethylene Vinyl Acetate, EVA has such a wide use because it is unassailable by fungi and bacteria and in some cases can have an hypoallergenic and antitoxic treatment, as well as being a flexible and elastic product.

Among the best EVA materials that we know we can suggest the Multiform, available in different colors both smooth and perforated, and the ORTHOCONTACT color and multicolor that has the peculiarity of having special colors.

Among the best EVA materials that we know we can suggest the Multiform, available in different colors both smooth and perforated, and the ORTHOCONTACT color and multicolor that has the peculiarity of having special colors.

Antistatic fabrics are processed in such a way as to prevent the formation of electrical charges due to rubbing.

Antistatic fabrics are processed in such a way as to prevent the formation of electrical charges due to rubbing.

Natural leather is a widely used, versatile and elegant choice, excellent both in summer and winter. However, there are many varieties of leather and not all are of good quality, for us the best are the split goat and calfskin. The goatskin split is a rather thin but very fine goatskin, it is also available in the plus version with a more uniform flower and with fewer imperfections thanks to a particular tanning and processing.

Natural leather is a widely used, versatile and elegant choice, excellent both in summer and winter. However, there are many varieties of leather and not all are of good quality, for us the best are the split goat and calfskin. The goatskin split is a rather thin but very fine goatskin, it is also available in the plus version with a more uniform flower and with fewer imperfections thanks to a particular tanning and processing.

Calfskin leather instead is usually thicker than goatskin leather, thus providing, for those who wish, a material that is always natural but with greater thickness.

Calfskin leather instead is usually thicker than goatskin leather, thus providing, for those who wish, a material that is always natural but with greater thickness.

Modern materials are made with combinations of different polymers, born with the concept of providing the characteristics of natural leather but, at the same time, to eliminate the drawbacks. If the leather may have imperfections, irregularities in thickness or in some cases may break, the polymer materials have none of these defects.

Modern materials are made with combinations of different polymers, born with the concept of providing the characteristics of natural leather but, at the same time, to eliminate the drawbacks. If the leather may have imperfections, irregularities in thickness or in some cases may break, the polymer materials have none of these defects.

Materials made of polymers also have larger dimensions and length than natural leathers, are easily washable without being damaged and have greater tensile strength.

Materials made of polymers also have larger dimensions and length than natural leathers, are easily washable without being damaged and have greater tensile strength.

Aramica is made from special combinations of polymers and, in addition to having the characteristics of the fabrics mentioned above, can boast a special processing.

Aramica is made from special combinations of polymers and, in addition to having the characteristics of the fabrics mentioned above, can boast a special processing.

Home News The best coatings for insoles

The best coatings for insoles

When it comes to insole coverings, a vast universe of products opens up that is very varied, but where it's easy to get confused. Here we will try to provide you with a map that allows those who sail in this sea not to be lost and have a compass with which to orient themselves. To start with, we have to divide the materials into 5 different categories: EVA materials, antistatic fabrics, natural leather, polymers and new polymers.

-

EVA materials

There is a wide range of materials in Ethylene Vinyl Acetate, EVA has such a wide use because it is unassailable by fungi and bacteria and in some cases can have an hypoallergenic and antitoxic treatment, as well as being a flexible and elastic product.

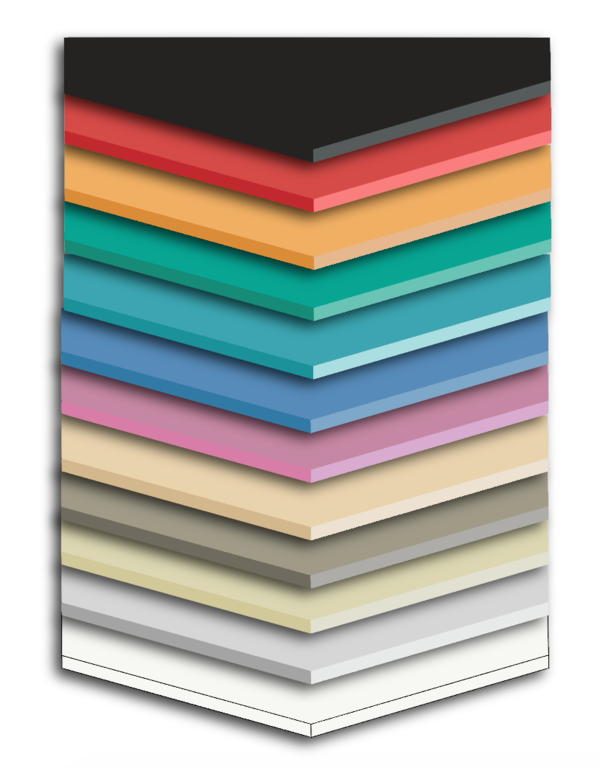

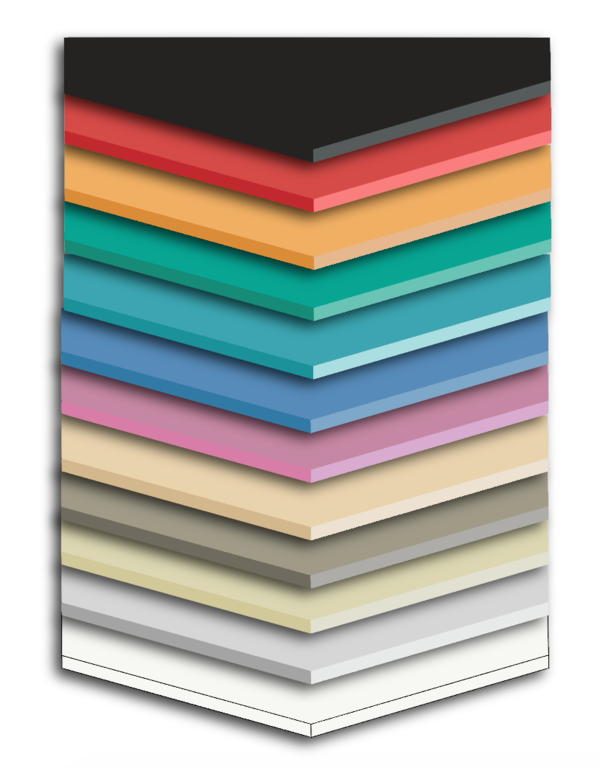

There is a wide range of materials in Ethylene Vinyl Acetate, EVA has such a wide use because it is unassailable by fungi and bacteria and in some cases can have an hypoallergenic and antitoxic treatment, as well as being a flexible and elastic product. Among the best EVA materials that we know we can suggest the Multiform, available in different colors both smooth and perforated, and the ORTHOCONTACT color and multicolor that has the peculiarity of having special colors.

Among the best EVA materials that we know we can suggest the Multiform, available in different colors both smooth and perforated, and the ORTHOCONTACT color and multicolor that has the peculiarity of having special colors.EVA materials have a very wide use and also a relatively low cost but, when it comes to insole coverings, there are many better quality materials. EVA is a closed-cell material, hygienic yes, but less comfortable than others, and this makes the difference in the construction of a quality footbed.

-

Antistatic fabrics

Antistatic fabrics are processed in such a way as to prevent the formation of electrical charges due to rubbing.

Antistatic fabrics are processed in such a way as to prevent the formation of electrical charges due to rubbing.Among the best anti-static fabrics we recommend those that have a processing inside with silver fibers such as Irotex II and Rox. This is a technical material made of 95% polyamide and 5% silver fibres: the silver fibres aim to make the material antibacterial, thus preventing the proliferation of bacteria and fungi on the surface of the fabric, and at the same time to drastically reduce bad smells. In addition to these characteristics, Irotex, thanks to a special membrane combined with the fabric, has the function of rebalancing body heat according to the outside temperature.

-

Natural leather

Natural leather is a widely used, versatile and elegant choice, excellent both in summer and winter. However, there are many varieties of leather and not all are of good quality, for us the best are the split goat and calfskin. The goatskin split is a rather thin but very fine goatskin, it is also available in the plus version with a more uniform flower and with fewer imperfections thanks to a particular tanning and processing.

Natural leather is a widely used, versatile and elegant choice, excellent both in summer and winter. However, there are many varieties of leather and not all are of good quality, for us the best are the split goat and calfskin. The goatskin split is a rather thin but very fine goatskin, it is also available in the plus version with a more uniform flower and with fewer imperfections thanks to a particular tanning and processing. Calfskin leather instead is usually thicker than goatskin leather, thus providing, for those who wish, a material that is always natural but with greater thickness.

Calfskin leather instead is usually thicker than goatskin leather, thus providing, for those who wish, a material that is always natural but with greater thickness.However, leather also has some drawbacks: it is not always easy to work, very often there are difficulties both with regard to imperfections on the surface, both for the thickness not always uniform. In short, natural leather certainly has its merits, but also its defects and drawbacks, which, however, can be overcome thanks to polymers.

-

Polymers

Modern materials are made with combinations of different polymers, born with the concept of providing the characteristics of natural leather but, at the same time, to eliminate the drawbacks. If the leather may have imperfections, irregularities in thickness or in some cases may break, the polymer materials have none of these defects.

Modern materials are made with combinations of different polymers, born with the concept of providing the characteristics of natural leather but, at the same time, to eliminate the drawbacks. If the leather may have imperfections, irregularities in thickness or in some cases may break, the polymer materials have none of these defects. Materials made of polymers also have larger dimensions and length than natural leathers, are easily washable without being damaged and have greater tensile strength.

Materials made of polymers also have larger dimensions and length than natural leathers, are easily washable without being damaged and have greater tensile strength.Obviously, there is a wide choice of polymer-based coatings, different price ranges and different degrees of quality: Softi is an inexpensive but very good polymer, Drem and Drem lux are already high quality polymers that, even by touch and appearance, are reminiscent of natural leather, while Nuage is a high quality polymer with a workmanship that makes it more resistant and more elastic than the others.

If you want to aim for perfection, however, you need to rely on new polymers and the best among them is certainly the Aramica.

-

New combinations of polymers, the Aramica

Aramica is made from special combinations of polymers and, in addition to having the characteristics of the fabrics mentioned above, can boast a special processing.

Aramica is made from special combinations of polymers and, in addition to having the characteristics of the fabrics mentioned above, can boast a special processing.Aramica is a product patented as early as 1994 specifically for insole coverings and which, over time, has gradually been perfected to become the ultimate in orthopaedic coverings.

Aramica, in addition to being more resistant than other normal polymers, can boast a series of additional processes that make it particularly soft and ductile as well as having antibacterial and anti-odour properties.

To this day, Aramica is regularly used by the most important operators in the orthopaedic technique sector (INAIL, Lab-or, Sant'Orsola, etc.) and is a point of reference when it comes to special coatings for personalised insoles and quality orthoses.